A Day at the Races

On a warm Sunday afternoon in May at the SlyFox Brewing Company’s Annual Bock Fest and Goat Race, the most unlikely of competitors rose to the top of a field of about 40 to bask in the radiant glow of the winner’s circle…

Dayhill Mitigates Construction Risk, Rock Lititz Expansion Keeps Rocking

Rock Lititz has enjoyed exponential growth, and Dayhill is excited to mitigate construction risk to make sure the work keeps rocking. Rock Lititz is a collaborative community of the top production-based vendors and resources in the live event industry. Located on a 96-acre campus in the heart of the coolest small town, Lititz, PA, the Rock Lititz Campus hosts The Studio anchor tenant, a boutique hotel, several multi-tenant facilities, walking trails and more. With new growth happening all of time, Dayhill is pleased to provide Construction Monitoring Services at Building Pod 5 of this one-of-a-kind property.

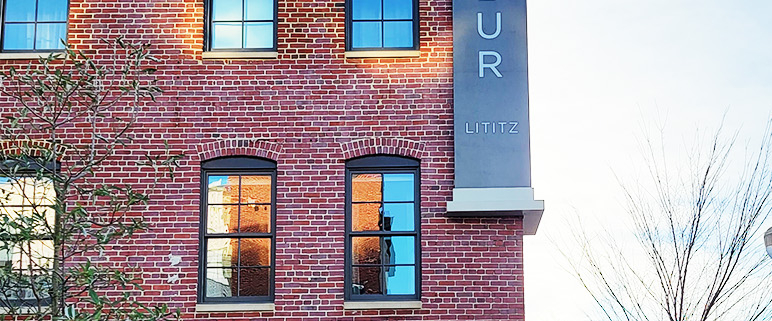

Dayhill’s Construction Monitoring Brings Sweet Success: The Wilbur Lititz

Construction monitoring is a wise investment for any project, and the latest historic revitalization project in Lititz, Pennsylvania was no exception. More than a century old, the Wilbur chocolate factory is a steadfast fixture of the Lititz, PA landscape.

Black Swan Event: Are you ready for the next one?

Anyone alive in the past few years knows all too well what a black swan event is, even if you are unfamiliar with its moniker. As defined above, the pandemic was our most recent black swan event…

Your Cost to Complete: Do You Have a Clear Picture?

Anthony “Bud” Stewart

VP, Funds Control Division

Your cost to complete a project hinges on a variety of known and unknown factors. On a prior blog post, we focused on the importance of a contract’s “Schedule of Values”. As emphasized in that post, the Schedule of Values must be a well delineated listing of all the tasks that constitute the project. The more detail, the clearer the project comes into focus. However, even the most detailed Schedule of Values is only one half of the picture. While the Schedule of Values describes the tasks that must be completed to produce revenue for the contractor, an important part of the picture remains undeveloped. A Schedule of Values does not reflect the costs that the contractor will incur when accomplishing the defined tasks. A lack of detail in this area creates a blurry image. A properly designed and implemented Funds Administration process will produce a fully developed picture by zooming in for the details.

When a project is being managed under Funds Administration, you can expect that each task will be associated with the party responsible for completion of that task. If the task has been delegated to a subcontractor, the name of that subcontractor and the amount of the subcontract will be known. Each subcontract is obtained to determine the subcontractor’s scope of work, and these defined tasks are compared against the Schedule of Values that the contractor submits to the owner. When disbursing funds, the subcontractor’s requisition for payment is analyzed against the corresponding line item on the Schedule of Values, and the amount of that line item, paid by the owner. These procedures ensure that the performing parties are satisfied.

Under Funds Administration, a sharp image of every function that has not been ‘subbed out’ is also developed. A depth of field on each of the contractor ‘self-performed’ functions is ascertained. The labor and material costs required to complete each item on the Schedule of Values is determined. All material suppliers are identified, and the budget for each of these suppliers is revealed. With this expense data, as the project develops, it will be determined if the material and labor costs will exceed the contractor’s expectations.

As you can clearly see, Funds Administration will produce a high-resolution picture.

The Contractor Evaluation: think outside the numbers

Joe Lawn Vice-President, Business Development Dayhill Group

When it comes to finding the right contractor for your commercial construction project, there is no one-size-fits-all approach. Every project is unique producing a different set of drivers to reach your end result. Properly vetting your commercial contractor through a contractor evaluation is a practice that must happen early in the process. While it may be tempting to choose the lowest bidder, this practice often leads to troubled or outright failed projects. Bid numbers aside, a contractor should be measured by key performance indicators that will afford you an in-depth look into their ability to deliver the project successfully.

Collect the Appropriate Information for your Next Contractor Evaluation

Brief Company History

Largest Projects Completed in the Last 3 to 5 Years

Work in Progress (WIP)

Key Employees

Estimating Information

Typical Work

Method Used to Monitor Cost

Major Equipment Owned by the Company

Business Volume in the Last 3 Years

Information on Safety Program

Financial Statement

Last 3 years if available, and a current interim statement

General Contractor’s License

Plans for Future Growth

The information you garner from this simple exercise can give you some perspective on the quality and history for the end game of the most qualified Contractor for your project.

So, what are the next steps?

- Define the status of the information available or presented by the Contractor.

- Understand what drives the results of your evaluation.

- Seek and maintain high quality project management, labor, and field supervision personnel throughout the project. {ongoing evaluation from your monitoring group}

Finding the right contractor for your project goes well beyond the bid process. A carefully vetted contractor will check off a lot more of your boxes than simply the bottom line number. They will be the right one for the job at hand, regardless of price, which will save you so much more than if you simply ran with the lowest bidder.

Dayhill Group

Dayhill Group